销售热线:15060899237

电话:0595-86799999

传真:0595-86783555

电子邮件:xdm.neo@gmail.com

高压磨粉机系列High Pressure Mill Series

一、产品简介Product Description

高压悬辊磨粉机适用于研磨重晶石、石灰石、陶瓷、矿渣等莫氏硬度不大于9.3级,湿度在6%以下的非易燃易爆的物料。该设备适用于矿山、冶金、化工、建材等行业280多种物料的高细制粉加工,成品粒度在80-425目范围调节(最细可达800目)。

High Pressure Suspension mill is mainly made up of the mainframe, separator, blower, finished powder cyclone collector, bag filter and connecting pipes, etc.It can produce powder from various non-flammable and non-explosive mineral materials with Mohs hardness below 9.3 and humidity below 6%, such as barite, limestone, kaolnite, ceram and slags, etc. The Product size is adjustable in the range of 80-425 mesh. It is possible to produce 30-80 mesh coarse powder through special device in the machine if necessary.

二、技术参数 Technical Data

|

型号 Model |

磨辊数 Roller Number |

磨辊尺寸Roller Size(mm) |

最大进料 Max .Feeding Size (mm) |

成品粒度 Size of finished product (mm) |

产量 Capacity(t/h) |

主机功率 Host Power (KW) |

风机 功率 Blower Power (KW) |

外形尺寸 Dimension (L×W×H)(mm) |

|

| YGM7815 | 3 | 260×150 | 15-20 | 0.613-0.045 | 0.28-3 | 18.5 | 15 | 4300×3500×5100 | |

| YGM8314 | 3 | 270×140 | 15-20 | 0.613-0.045 | 0.35-3.4 | 22 | 22 | 5300×4100×5200 | |

| YGM9517 | 4 | 310×170 | 15-25 | 0.613-0.045 | 1.5-6.5 | 37 | 37 | 7100×5900×7900 | |

| YGM4121 | 5 | 410×210 | 15-25 | 0.613-0.045 | 3-12 | 75 | 75 | 7850×8000×9700 | |

| YGM160 | 6 | 440×270 | 15-35 | 0.613-0.045 | 5-20 | 132 | 132 | 12550×5700×8350 | |

工作过程Working Principle

YGM系列高压磨粉机内,磨辊吊架上紧固有l000一l500公斤压力的高压弹簧。开始工作后,磨辊围绕主轴旋转,并在高压弹簧与离心力的作川下,紧贴磨环滚动,其滚动压力比同等动力条件下的雷蒙磨粉机高20%,故产量大为提高。当被磨物料进入磨腔后,由铲刀铲起送入磨辊与磨环之间进行碾压,碾压后的粉末随鼓风机的循环风带入分析机,合格细粉随气流入旋风集粉器即为成品,大颗粒物粒落后重磨。循环风返回鼓风机再重复以上过程,余风则进入袋式除尘器净化。 当磨辊与磨环达到一定磨损后,调整高压弹簧长度,保持磨辊与磨环之间恒定碾压力,从而保证稳定的产量与细度。

The whole structure of this machine consists of main engine, air blower ,size analyzer, cyclone collector , bag-type dust filter and pipeline,etc.which, if required,can be selectively equipped with elevator, electromagnetic vibrating feeder, crusher, electric cabinet, etc,. Having been crushed into the desired size ,and delivered to the hopper by bucket elevator, materials will be fed evenly and continuously by the vibrating feeder into the grinding chamber for powder-processing. Then the shovel scoops up the materials to the space between roller and ring,in which the grinding roller rotates itself as well as around the vertical axis, and then presses the grinding ring closely due to centrifugal force to accomplish the grinding. Fine powders will be carried to cyclone collector by the blower after analyzing, and then piped out as the finished products. Rough materials will be recycled into the grinding chamber by the air for regrinding. The materials may contain some moisture, and the pipeline joints are not absolutely airtight, therefore the external air might be sucked in,which will disturb the air circulation balance but can be achieved through adjusting air pipe between the air blower and the main engine. In this way, the superfluous air current will be channeled into the bag-type dust filter which will collect powder carried by the air and discharge the superfluous air after being purified.

|

名称 Name |

处理量Capacity(t/h) | ||||||||

| 1.5-6.5 | 3-12 | 5-20 | |||||||

|

型号 Model |

功率Power (kw) |

型号 Model |

功率Power (kw) |

型号 Model |

功率Power (kw) |

||||

|

磨粉机主机 Main engine |

主机 Host machine | YGM9517 | 37 | YGM4121 | 75 | YGM160 | 132 | ||

| 分析机 Analytical engine | YGM9517 | 5.5 | YGM4121 | 7.5 | YGM160 | 11 | |||

| 风机 Draught fan | YGM9517 | 37 | YGM4121 | 75 | YGM160 | 132 | |||

| 辅机部分 Auxiliary Machines | YGM9517 | YGM4121 | YGM160 | ||||||

| 除尘部分Dust removing equipment | YGM9517 | YGM4121 | YGM160 | ||||||

|

配套设备 Controller equipment |

颚式破碎机 Jaw Crusher | PE200×350 | 7.5 | PE200×400 | 15 | PE250×750 | 22 | ||

| 提升机 Bucket Elevator | 3 | 4 | 4 | ||||||

| 给料机 Feeder | 0.2 | 0.2 | 0.2 | ||||||

|

电控柜 Eontroller Cabinet |

专用 Special use | YGM9517 | 90.2 | YGM4121 | 176.7 | YGM9517 | 301.2 | ||

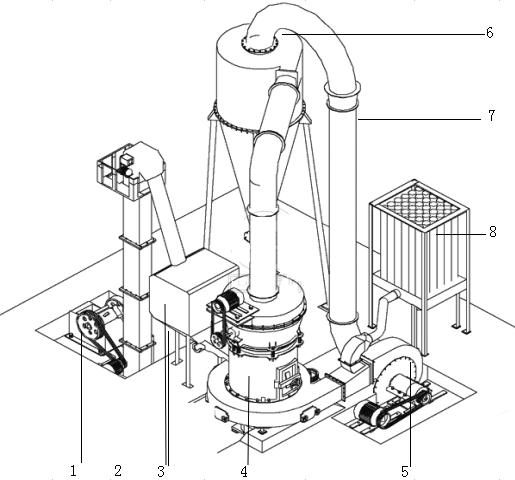

1、颚式破碎机 Jaw Crusher

2、提升机 Bucket Elevator

3、料仓 Storage Silo

4、主机 High Pressure Micro-Powder Grinder

5、风机 Blower

6、集粉器Powder Collector

7、除尘器Filter

8、管道部分Piping Device